Make a hole in the cylinder liner

Defect description and review

Creating a cavity in the hydrothermal zone that penetrates into the cylinder cylinder liner as it becomes larger. This defect happens to all diesel engines that run wetter.

The vibration and vibration of the cylinder by the combustion pressure and the lateral forces applied by the piston cause the formation of invasive bubbles in the water, which leads to the destruction of the protective layer created by the antifreeze and the perforation of the cylinder linering.

This defect, known as bubble corrosion, is the result of the formation and collision of bubbles from the coolant with the metal surface.

Bubbles caused by the high velocity of the coolant flow and a sudden change in direction hit the metal surface, creating a force of 60,000 ps, damaging the surface and creating cavities.

Causes:

- Abrasion between the cylinder liner and the piston

- The Bosch inside the cylinder is not installed well.

- Inadequate piston and rim size and use of pistons that have been used before.

- There is a technical defect in the thermostat that prevents the linering and piston from reaching the proper operating temperature.

- Vibration due to increasing distance and allowable looseness between the liner and the piston.

- If the engine has not reached sufficient temperature, the coolant pressure is too low, facilitating the formation of water vapor bubbles.

- Reduces the level of coolant, which allows air to enter the coolant and the water chamber.

- Air enters the cooling system from any source.

- Leakage in various parts of the cooling system such as radiator cap, water pipes and hoses and clamping

connections

Technical defects in these parts lead to a lack of coolant and a decrease in fluid pressure, and as a result, the coolant reaches the boiling point sooner.

- Use water alone to cool the system

- The presence of salt, calcareous and acidic salts in water as a coolant.

- Inadequate antifreeze.

- Lack of sufficient antifreeze, which leads to the formation of steam bubbles.

- Driving under conditions where the cooling system is leaking and the engine temperature is high.

Solution:

- Eliminate the causes of the defect.

- Keep the engine cooling system clean.

- Do not use water with a hardness higher than 170 ppm

- Always check the antifreeze level before driving. When the engine is cold, the coolant level should be between the MAX and MIN points.

- Complete replacement of antifreeze every 2 years

- Use a ratio of 50 to 60 percent antifreeze with 40 to 50 percent water.

- After several hours of driving, allow the engine to idle for 1 minute before switching off the engine and removing the switch, then switch off the engine. This helps reduce heat shock in the engine and prevents the coolant from draining from the cooling system all at once.

Rounding of the upper edge of the cylinder liner

Defect description and review

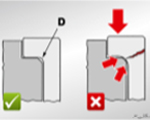

Definition: Detachment of the stepped part above the cylinder head liner.

The edged part of the liner is completely detached from it.

The crack starts from the bottom of the edge and grows along the axis of the liner with an approximate angle of 30 degrees in the cross section and begins to move circumferentially.

Causes of occurrence

- Existence of foreign body, dirt and pus at the place where the liner sits on the cylinder.

-

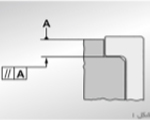

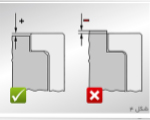

(Figure1) - Existence of distortion at the contact surface of the linering and cylinder edges and the non-parallelism of these two edges relative to each other. (Figure1)

- Use of non-standard washers in terms of material, diameter and shape.

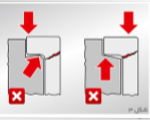

- No use of torque, angle, sequence and sequence of closing the cylinder head bolts.

-

(Figures 2 )

(Figures 3) - Failure to observe the proper distance and angle between the surface of the liner seat on the cylinder block and its edge (Figures 2 , 3).

- The edge of the linering is not in a good position relative to the surface of the cylinder and cylinder head. (Figure4)

Solution:

- Eliminate the causes of the defect

- Make sure that the cylinder liner seat is machined accurately on the cylinder block. (Figure 5)

- Make sure that the liner seat is smooth by controlling the smoothness of the cylinder surface at the edge of the liner by inking the cylinder edge surfaces and seeing the ink effects on the cylinder liner edge.

Cylinder liner failure due to water confinement

Defect description and review

Gripping and deformation of the piston with breaking of the inner surface of the cylinder cylinder liner.

The inner surface of the cylinder liner and in its upper part suffers from deep cracks and fractures, and also the effects of piston grip are visible on the inner surfaces of the cylinder liner.

Causes of occurrence

- Water enters the engine due to the car passing through the water.

- Leakage in the cylinder head due to its defect and as a result of leakage of water or other liquids into it.

- Leakage in fuel injection needles and accumulation of fuel in the cylinder when the engine is off.

Find a solution

- The car should not pass over water that is so high that water is likely to enter the engine.

- Inspect the engine and replace defective fuel injection needles.

Dark effects on gloss on top of cylinder liner

Defect description and review

This defect occurs in the inner and upper part of the cylinder liner so that the polishing lines (honing) in this area are completely eliminated and no trace of erosion or grip is seen on the piston.

Causes of occurrence

- Improper and poor quality engine oil use.

Oil burning and accumulation along with abrasion of this burnt oil, by the piston in the upper part of the piston course inside the cylinder liner. - Defective oil inlet valve.

Excess oil enters the combustion chamber

Find a solution

- Use oils recommended by car manufacturers.

- The amount of polishing (honing) should be applied to the recommended and standard amount.

- Check the surface quality of the piston ring.

- Check the inlet valves and replace them if they are worn and defective.

Rugged cylinder liner wear

Defect description and review

This defect occurs as a mirror-like coating and glaze on the inner surfaces of the cylinder liner. The sealing quality of the piston ring affects the polished surfaces of the liner, especially the dry liner, and can adversely affect the liner seal against oil and burnt gauze, and increase engine oil consumption.

Causes of occurrence

- Do not tighten the cylinder head bolts with standard torque and sequence.

- Loss of surface smoothness between cylinder block and cylinder head by improperly tightening screws.

- Use unsuitable screws for the cylinder head.

- The contact surface of the cylinder block with the cylinder linering and its edge is out of standard size or damaged.

- The presence of a foreign object at the point of contact of the coolant and the cylinder block in wet cylinder lineres.

Stiffness is very important for dry cylinder lineres. Do not have the cylinder liner too tight or too loose. - In cases where dry cylinder lineres are assembled by pressure or vibration.

Find a solution

- Use a suitable cylinder head gasket.

- Arrange the screws according to the manufacturer’s instructions.

- Check the smoothness of the surface and cleanliness at the point of contact of the cylinder block with the cylinder head.

- Since dry cylinder lineres have a small thickness, the presence of a small amount of dirt on their surfaces causes its size to exceed the standard, so their cleanliness should be checked.

Defect description and review

Mostly vertical cracks that occur at the edge of the flange (step) or the bottom edge. These types of cracks are more common in dry cylinder lineres and start vertically from the upper or lower edge of the cylinder liner and extend.

Causes of occurrence

- Carelessness during transport, handling, repair and installation.

- Lockings caused by poor quality oil.

- The presence of a foreign object on the surfaces of the edge of the cylinder liner and the cylinder.

- Improper installation of the cylinder liner, especially at the edge.

Find a solution

- Convenient transportation.

- Do not place heavy objects on the cylinder liner.

- Keep surfaces that should be sealed clean.

- Care and caution when transporting and performing repairs on the engine.

- In the event of a car accident or fall, the cylinder lineres should be measured and inspected by tools. It should be noted that the presence of small cracks leads to cracking and failure of the cylinder liner during engine operation.

Reference

- “Piston damage- recognizing and rectifying”

MS Motor Service International GmbH

- “ An overview of cavitation corrosion of diesel cylinder liners”.

Richard D.Hercamp.

- “cavitation erosion of diesel engine wet cylinder liners”.

Yu.kang zhou, jiu – gen he and F.G.Hamitt

- “Failure analysis of a cylinder sleeve from a turbocharged diesel engine ”

. W.hormaza, L.Mateus , A.Maranon

- “keep your cool”. Neil Robinson

- Maintaining Diesel engines for Relible Operation

- Driver,s Hand book FM,FH

- “Engine components and filters: damage profiles, probable causes and prevention”. MAHLE technical informatio

PRODUCT

Read More

- Types of cylinder liner

- Wet cylinder liner Install

- Cylinder liner

- Installing Cylinder Liners

- Products (types of diesel and petrol cylinder liner)

- What Is Cylinder Liner? | Material for Cylinder Liner | Function of Cylinder Liner | Types of Cylinder Liner

- What is a cylinder liner and the introduction of all types of cylinder liners in Gasoline and Diesel engines

- What is a cylinder liner?